Bellary Road, Bangalore, Karnataka

- GST NO. : 29AAKFL2846H1ZZ

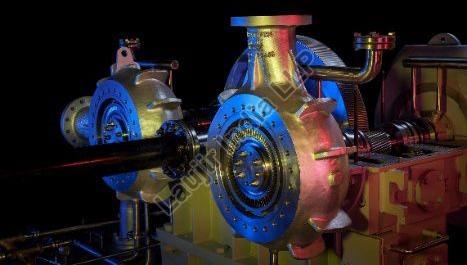

Steam Turbines

Leading Manufacturers, Exporters and Wholesaler of Extraction Cum Back Pressure Steam Turbines, Overhung Back Pressure Cum Condensing Steam Turbines, Steam Extraction Cum Condensing Turbine and Straight Condensing Steam Turbine from Bangalore.

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Industrial |

| Country of Origin | India |

| Power | 50Kw - 100MW |

| Generator/Alternator Type | Steam |

| Power Capacity | 50KW - 100MW |

| Speed | Turbine: 3000 - 15000 RPM |

| Steam Exhaust | 4 - 300 Ton/Hr, 0.1/0.2 Bar |

| Steam Inlet | 4 - 300 Ton/Hr |

| Power Generation | 50Kw - 100MW |

Preferred Buyer From

| Location | Worldwide |

Turbine Design Features:

1. Efficient and Compact Design: The turbine design is customized to be efficient and compact, with an integral tank for streamlined operation and space-saving installation.

2. Single and Multiple Extraction:The turbine offers options for single and multiple extractions at determined pressure and flow rates, providing flexibility to meet varying process requirements.

3. Horizontally Split Single Cylinder Design:Featuring a horizontally split single cylinder design, the turbine ensures ease of maintenance and servicing.

4. Radial and Axial Exhaust Flow Options:The turbine is available in both radial and axial exhaust flow configurations, catering to different installation and operational preferences.

5. Hydraulically Operated Emergency Valve and Electro-Hydraulic Governing System:Equipped with a hydraulically operated emergency valve and an electro-hydraulically controlled governing system, the turbine ensures reliable and precise operation under varying conditions.

6. Dynamically Balanced Forged Steel Rotor:The turbine rotor is dynamically balanced and made from forged steel, ensuring smooth and stable operation even at high speeds.

7. Alloy Steel Blades:The turbine blades are constructed from high-quality alloy steel, providing durability and resistance to wear and corrosion.

8. Tilting Pad Thrust and Journal Bearings:Utilizing tilting pad thrust and journal bearings, the turbine minimizes friction and ensures smooth rotation, enhancing efficiency and reliability.

9. Vibration and Temperature Monitoring System:The turbine is equipped with a vibration and temperature monitoring system to detect and address potential issues proactively, ensuring safe and efficient operation.

10. Power Output:The turbine is capable of generating power output up to 35 MW for new machines and 220 MW for used machines, catering to a wide range of power generation needs.

11. Operating Parameters:Inlet pressure: Up to 142 Kg/Cm2 G Inlet temperature: Up to 550 degrees Celsius

This customized turbine design offers advanced features and robust construction, making it suitable for various industrial applications where efficiency, reliability, and performance are paramount.

| Business Type | Manufacturer, Exporter, Supplier |

| Power Capacity | 3000 kW |

| Water Flow Range | 25 TPH |

| Inlet Steam Temperature | Upto 520 deg |

| Speed | 7000 RPM |

| Max Inlet Temperature | 87 kg |

| Frequency | 50 Hz |

| Inlet Temp | 520 Deg |

| Max Exhaust | 12 kg |

Preferred Buyer From

| Location | Worldwide |

Overhung Design Condensing and Back Pressure Steam Turbines

Overhung Design Turbine system is designed to conserve unutilized pressure energy in a Process Plant, specifically by utilizing PRV/PRDS (Pressure Reducing Valve/Pressure Reducing Desuperheater) systems that would otherwise simply throttle excess steam pressure. The ECT reduces steam pressure to the required process (back) pressure while converting the pressure energy into high velocity to rotate the turbine wheel at a speed of 12000 RPM. This high-speed rotation is then reduced through a reduction gearbox to 1500/3000 RPM to generate incidental clean, green electric power.

Key Features:

1. Versatile Steam Utilization:The ECT system can utilize saturated steam, making it highly beneficial for industries using saturated steam for various processes.

2. Turbine Frames:The system is available in different frames to accommodate varying power requirements: Frame A (up to 250 KW), Frame 2 (251 to 750 KW), and Frame 3 (751 to 3500 KW).

3. Turbine Highlights:Stainless steel construction of all steam-wetted parts ensures long corrosion-free life.Precision CNC milled aerodynamic blading maximizes turbine efficiency.The turbine is machined from a solid hardened stainless steel forging for maximum durability.Hardened and ground precision helical gears ensure long-life and smooth operation.The unit is designed for low noise and high efficiency, with a unitary skid for all equipment, providing a single compact and factory-assembled unit.The system is fully automated, requiring no dedicated operator, and includes redundant in-built safety features for reliability and safety.The system offers industries a cost-effective and environmentally friendly solution for harnessing excess steam pressure to generate clean electric power, contributing to energy conservation and sustainability initiatives.

| Business Type | Manufacturer, Exporter, Supplier |

| Power | 50Kw - 100MW |

| Usage/Application | Power Generation / Pump |

| Pressure Range | 8.5 - 105 Ata |

| Generator/Alternator Type | Steam |

| Power Capacity | 50KW - 100MW |

| Water Flow Range | 4 - 300 Ton/Hr |

| Material | IBR / Alloy Steel / ASTM |

| Speed | Turbine: 3000 - 15000 RPM |

| Power Generation | 50Kw - 100MW |

Preferred Buyer From

| Location | Worldwide |

Turbine Design Features:

1. Efficient and Compact Design: The turbine design is customized to be efficient and compact, with an integral tank for streamlined operation and space-saving installation.

2. Single and Multiple Extraction:The turbine offers options for single and multiple extractions at determined pressure and flow rates, providing flexibility to meet varying process requirements.

3. Horizontally Split Single Cylinder Design:Featuring a horizontally split single cylinder design, the turbine ensures ease of maintenance and servicing.

4. Radial and Axial Exhaust Flow Options:The turbine is available in both radial and axial exhaust flow configurations, catering to different installation and operational preferences.

5. Hydraulically Operated Emergency Valve and Electro-Hydraulic Governing System:Equipped with a hydraulically operated emergency valve and an electro-hydraulically controlled governing system, the turbine ensures reliable and precise operation under varying conditions.

6. Dynamically Balanced Forged Steel Rotor:The turbine rotor is dynamically balanced and made from forged steel, ensuring smooth and stable operation even at high speeds.

7. Alloy Steel Blades:The turbine blades are constructed from high-quality alloy steel, providing durability and resistance to wear and corrosion.

8. Tilting Pad Thrust and Journal Bearings:Utilizing tilting pad thrust and journal bearings, the turbine minimizes friction and ensures smooth rotation, enhancing efficiency and reliability.

9. Vibration and Temperature Monitoring System:The turbine is equipped with a vibration and temperature monitoring system to detect and address potential issues proactively, ensuring safe and efficient operation.

10. Power Output:The turbine is capable of generating power output up to 35 MW for new machines and 220 MW for used machines, catering to a wide range of power generation needs.

11. Operating Parameters:Inlet pressure: Up to 142 Kg/Cm2 G Inlet temperature: Up to 550 degrees Celsius

This customized turbine design offers advanced features and robust construction, making it suitable for various industrial applications where efficiency, reliability, and performance are paramount.

| Business Type | Manufacturer, Exporter, Supplier |

| Usage/Application | Industrial |

| Power | 5MW |

| Pressure Range (Inlet) | 8 Bar |

| Pressure Range (Outlet) | Max 6.5 |

| Speed (RPM) | 7500 RPM |

| Application | Power |

| Frequency | 60 Hz. |

| Output Voltage | 10500 V |

| Inlet Steam Temperature | 260 -535 Degree C |

Preferred Buyer From

| Location | Worldwide |

Turbine Design Features:

1. Efficient and Compact Design: The turbine design is customized to be efficient and compact, with an integral tank for streamlined operation and space-saving installation.

2. Single and Multiple Extraction:The turbine offers options for single and multiple extractions at determined pressure and flow rates, providing flexibility to meet varying process requirements.

3. Horizontally Split Single Cylinder Design:Featuring a horizontally split single cylinder design, the turbine ensures ease of maintenance and servicing.

4. Radial and Axial Exhaust Flow Options:The turbine is available in both radial and axial exhaust flow configurations, catering to different installation and operational preferences.

5. Hydraulically Operated Emergency Valve and Electro-Hydraulic Governing System:Equipped with a hydraulically operated emergency valve and an electro-hydraulically controlled governing system, the turbine ensures reliable and precise operation under varying conditions.

6. Dynamically Balanced Forged Steel Rotor:The turbine rotor is dynamically balanced and made from forged steel, ensuring smooth and stable operation even at high speeds.

7. Alloy Steel Blades:The turbine blades are constructed from high-quality alloy steel, providing durability and resistance to wear and corrosion.

8. Tilting Pad Thrust and Journal Bearings:Utilizing tilting pad thrust and journal bearings, the turbine minimizes friction and ensures smooth rotation, enhancing efficiency and reliability.

9. Vibration and Temperature Monitoring System:The turbine is equipped with a vibration and temperature monitoring system to detect and address potential issues proactively, ensuring safe and efficient operation.

10. Power Output:The turbine is capable of generating power output up to 35 MW for new machines and 220 MW for used machines, catering to a wide range of power generation needs.

11. Operating Parameters:Inlet pressure: Up to 142 Kg/Cm2 G Inlet temperature: Up to 550 degrees Celsius

This customized turbine design offers advanced features and robust construction, making it suitable for various industrial applications where efficiency, reliability, and performance are paramount.