Bellary Road, Bangalore, Karnataka

- GST NO. : 29AAKFL2846H1ZZ

| Business Type | Manufacturer, Exporter, Supplier |

| Color | Available In Various Colours |

| Condition | New |

| Automatic Grade | Automatic |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

Additional Specifications and Considerations:

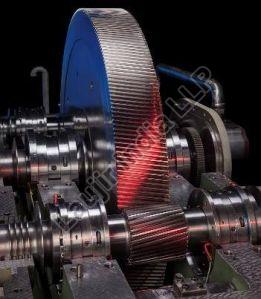

1. Gears Conforming to DIN4/DIN5 Accuracy:The turbine features gears conforming to DIN4/DIN5 accuracy standards, ensuring precise and reliable operation.

2. Hydrodynamic Bearings:Bearings are hydrodynamic, either white metal or tilting pad, providing robust support and minimizing friction for smooth rotation.

3. Forced Lubrication:The lubrication system utilizes forced lubrication to ensure adequate oil distribution and cooling, enhancing gear and bearing performance.

4. Turning Gears:Mostly turning gears are required in the turbine design, facilitating efficient power transmission and control.

5. Critical Speed Considerations:Critical speed is carefully accounted for during the design process to prevent resonance and ensure safe operation under various conditions.

6. Skews (Vertical and Horizontal):Both vertical and horizontal skews are carefully considered to optimize gear meshing and minimize noise and vibration.

7. Low Viscosity Lubrication Oil:The lubrication oil used in the system has low viscosity, facilitating efficient lubrication and heat dissipation.

8. Tip Correction and Thermal Correction:Tip correction, including thermal correction, is integrated into the design process to optimize gear performance and minimize wear.

9. Shifting of Center of Casing Due to Heat:The design accounts for the shifting of the center of the casing due to heat, ensuring proper alignment and preventing structural issues.

10. Double Helical Gearbox:A double helical gearbox is employed to counter axial thrust and improve overall efficiency, ensuring smooth and reliable operation.

Additional Information

| Standard/ Component | Japanese JIS | German DIN | American ASTM | British BS | Indian Standard IS | European EN/ISO | |

| Gear Wheel & Pinion Shaft (case hardened) | SNCM 415/ SNCM 420 | 17CrNiMo6 DIN 17210 | AISI 4320/8620/ 9310 | 815M17 | 15Ni7Cr4Mo2 IS:4432 | 18CrNiMo7-6 EN 10084 : 2008 | |

| JIS G 4103 | 820M17 BS 970 | ||||||

| Gear Wheel & Pinion Shaft (through hardened) | SNCM439/ SNCM447 JIS4103 | 34CrNiMo6/ 30CrNiMo8 DIN 17200 | AISI 4145/AISI 4340 | 817 M40 BS:970 | 42 Cr4M02 | 34CrNiMo6 / 30CrNiMo8 EN 10083-3 | |

| Gear Wheel Shaft | SCM 440 | 42CrMo4V DIN 17200 | AISI 4140 | 709 M40 BS:970 817 M 40 | 42 Cr4M02 | 42 CrMo4 | |

| JISG 4105 | 34CrNiMo6 | AISI 4340 | 40 NiCR4 Mo3 | 50CrMo4 EN 10083/3 : | |||

| Fabricated Casing | SS 400 JIS3101 | ST-42-2 DIN17100 | ASTM A 283 Grade D | - | GRADE E 250A,IS:2062 | S225JR/S275JE N10025-2 | |

| Cast Casing | FC 250 | GG25/GG30 DIN1691 | ASTM A 48 Class 35B/40B | GRADE 250/300 BS1452 | FG 260/FG 300 IS:210 | EN GGL250/300 EN 1561 | |

| JISG 5501 | |||||||

| Bearing: White Metal Lining | WJ-2 JIS H 5401 | SnSb8Cu4/ ERGON791 | ASTM B 23-49 or SAE 11 | Grade A BS:3332 | Grade 84 IS:25:1979 | SnSb8Cu4 DIN/ISO 4381 | |

| Bearing: Steel Backed | S20C,S22C, S25C | C10/C15 DIN 1652 | AISI 1015/1020/ 1018 | 050A20 BS970 | Class 1A IS:2004 | C15 C10 |

Looking for "Turbo Gearbox For Gas Turbine" ?

Explore More Products